-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

- Tags - #PV2R pump

-

- Last updated August 30, 2019 0 comments, 297 views, 0 likes

- Taizhou - Get Directions

More from hong yi

More in Politics

Related Blogs

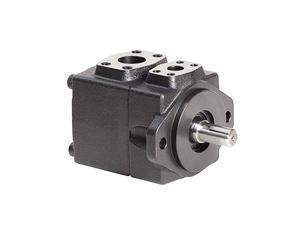

Understanding of PV2R Vane Pump

Body

Hongyi Hydraulic teaches you how to maintain PV2R pump?

1. If users do not use the oil pump in time after buying it back, they should inject anti-rust oil into the oil pump, coat the exposed surface with anti-rust oil, and then cover the dust cover of the oil port and keep it properly.

2. piping, residual iron filings and residues in the oil tank and pipeline, especially cloth, often cause oil pump failure, must pay attention to remove.

3. the relief valve regulating pressure should not be too high, generally 1.25 times the rated pressure of the pump.

4. Keep the oil temperature in the range of 10-60℃, the best range is 35-50℃, especially avoid high temperature continuous operation, otherwise the life of oil pump will be greatly shortened, and heater and cooling device will be installed when necessary.

5. To maintain the normal oil level, an oil level gauge should be set in the oil tank so that oil can be observed and replenished frequently.

6. regularly check the oil performance, can not meet the prescribed requirements to be replaced in time and clean the tank.

7. The oil filter should be cleaned frequently to ensure smooth oil suction.

8. After the oil pump works for a period of time (due to vibration), the mounting screw or the flange screw at the inlet and outlet of the oil pump may be loose. Attention should be paid to check and tighten to prevent loosening.

If you want to know more information, you can click here: https://www.vanepumpfactory.com/

Comments