The Lifting Ring Must Be Completely Screwed Into The Plastic Pail Mould

Corps

Our friends who are struggling in the production line know that there are some operating rules in Plastic Pail Mould. We must know that safety is productivity after all.

The injection molding machine is a kind of complex machine that runs quickly under high temperature and high pressure. The operator is often negligent, causing irreparable physical injury under carelessness, but regrets for life. Plastic medical mould The injection molding machine is dangerous in every step of the operation, especially when the mold is opened and locked. In order to avoid danger, the operator must pay attention to the following safety operation details during injection molding:

The injection molding factory keeps the injection molding machine and its surrounding environment clean and tidy at all times. The space around the injection molding machine is kept as unobstructed as possible. After adding lubricating oil or pressure oil, the leaking oil should be wiped off as soon as possible. Clean up the debris (such as rubber particles) on the melter tube before turning on the electric heater to avoid fire. If it is not necessary to overhaul the machine or when necessary, do not arbitrarily remove the heat shield on the melter tube.

Before injection molding, check whether the clamping can be terminated by pressing the emergency button or opening the safety door during operation.

When the shooting table is moved forward, do not use your hands to remove the deep glue leaking from the nozzle, so as to prevent your hands from being caught between the shooting table and the mold and causing physical damage. When cleaning the barrel, adjust the nozzle temperature to an appropriate higher temperature to keep the nozzle unobstructed, and then use a lower injection pressure and speed to remove the remaining rubber in the barrel. Do not touch it directly with your hands during cleaning. The rubber compound that has just been shot, so as not to be scalded.

Avoid leaving heat-sensitive and corrosive plastics in the barrel for too long, and strictly follow the shutdown and cleaning methods provided by the plastic supplier. When replacing plastics, make sure that the mixing of new and old plastics will not produce chemical reactions (such as POM and PVC mixing and heating will produce poisonous gas), otherwise other plastics must be used to remove the residual material in the barrel.

Do not cancel safety doors or safety switches in order to increase production speed. Before injection molding, check whether the mold is firmly installed on the movable template and head plate of the injection molding machine. Pay attention to whether the ground wire and other wiring of the injection molding machine are properly connected.

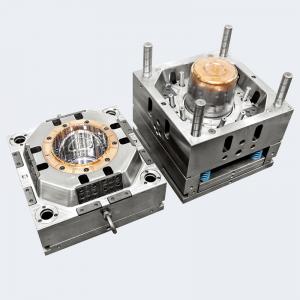

When installing the mold, the lifting ring must be completely screwed into the mold lifting hole before lifting. After the mold is installed, the length of the safety rod of the injection molding machine should be adjusted according to the size of the mold, so that when the safety door is opened, the machine safety stop (mechanical lock) can stop the injection molding machine from locking.

During the normal injection molding process, it is strictly forbidden for the operator to take out the injection molded parts from above or below the injection molding machine without opening the safety door. The oil pump motor of the injection molding machine should be turned off in time when inspecting the mold or temporarily not producing.

We are a professional molding company, sell different design of mold, Pail Mould Wholesale is one of them,welcome to visit our website.

commentaires