Please contact us for more information

الجسم

Laser-cut products are available in a variety of shapes and sizes, and they can be customized to meet specific customer requirements.

It was once thought that the use of laser-assisted glass polishing was limited to the creation of one-of-a-kind glass designs. That was until recently. Recent events, on the other hand, have shifted the situation. The situation has changed noticeably in recent years, though not significantly. By using laser printing to create a scratch-resistant pattern on the glass, it is possible to design the pattern to fit into a template, which is then used in the fabrication of glass products.

Coated glass allows you to transform a piece of glass into a sample or a different theme by exploiting the physical properties of the coating applied to it. This is especially useful when working with large pieces of glass. This will necessitate the use of a laser to achieve success.

In the last few months, we've finished the development of a patent-pending laserbird system that can be used in a variety of applications, including single-glazed panes, laminated glass, and insulated glass unit (IGU).

If you're looking for Laser Glass Finishing, HEGLABoraident offers this as a service to their clients.

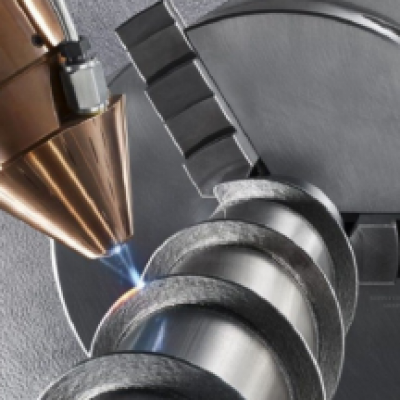

It is possible to create scratch-free surfaces on a variety of different materials by employing the laser decoating technique, which is described below.

Laser decoating is precise, and it does not degrade the surface on which it is applied, unlike the method used by this company. Some examples of customer applications for laser decoating, according to HEGLABoraident, include lighting effects behind mirrors and on machine controllers, among other things. It can be guaranteed that the final product will be crystal clear and free of scratches when the project is completed to the highest standard.

A new generation of smart glasses equipped with cutting-edge technology has become available in recent months.

According to the experts who have looked into the technology, using smart glass is yet another promising future technology that should be kept an eye out for in the not-too-distant future. For example, site-specific solar protection, radar attenuation near airports, and bird deterrent glass are all potential applications for bird protection glass. In contrast to traditional methods, using UniColor laser printing, as opposed to traditional methods, does not cause any damage to the glass and permanently adheres the marking to the pane without causing any damage to the pane itself (as opposed to traditional methods), as an illustration.

As a result of individual marking, it is possible to monitor and optimize the entire manufacturing process in real time, resulting in increased efficiency. The following are some examples of situations in which individual marking is used:It is possible to determine the manufacturer of an infrared grating unit (IGU) and the company that installed it for an end user using the HEGLABoraident laser system, assuming that the system is provided with sufficient information to perform the identification process. Multi-supplier projects save a significant amount of time when compared to traditional manufacturing methods, which is especially true when comparing the two.

تعليقات