Assembly lines have a long and distinguished history in the field of technological innovation and they are poised to have a bright future in this field

Corps

The Rompa Group employs a number of different manufacturing systems, including the assembly line, in the course of its business. These systems include the assembly line, for example. The term "manufacturing method" refers to the process of moving from one manufacturing station to another during the course of a manufacturing process in the engineering field. Each system stopping point results in the addition of new parts or assemblies to the system, and each system stopping point is the result of each other. Final product is found at the very end of the production line, near the end of the assembly line, and is labeled as such. It is also found at the very end of the assembly line. Assembly lines divide the work process into phases, which makes it easier to manage the work process in a more organized manner than it would be otherwise. Assembly lines are used to manufacture automobiles. Automobiles are assembled on assembly lines during the manufacturing process.

This is the story of how it all began....

Assembly lines are frequently cited as being invented by Henry Ford's company, which makes sense given that assembly lines are most commonly associated with automobile manufacturing. However, there is no evidence that Henry Ford's company was the first to use assembly lines. The evidence for this claim, on the other hand, is not conclusive. Historically, this is not a novel concept in the automobile industry; in fact, several companies began investigating it as early as the 1900s, according to historical records.

It has been discovered that organizations involved in the research and development of this type of manufacturing process have suffered a wide range of consequences as a result of their efforts. While working on the lines, employees were given the opportunity to learn about the specifics of their respective station locations, which they did for a period of time. As a result of their training, employees were able to quickly become acclimated to their surroundings and learn how to work efficiently at each station, resulting in extremely high productivity at each location as a result of their training. Vehicles, planes, and industrial equipment have all been improved as a result of the increased level of precision that has been achieved. It was possible for the industry to grow as a result of this development, which was beneficial to all parties involved.

Assembly lines are distinguished from other types of production lines by the purpose for which they are used, as opposed to other types of production lines. Assembly lines can be classified into the following four types, which are widely used across various industries and can be distinguished by their general appearance:

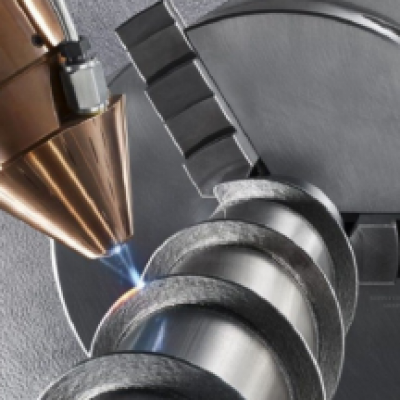

To ensure high quality standards throughout the manufacturing process, the Rompa Group manufactures its products on an automated assembly line, says the company. Most of the time, machines are used to operate these types of production lines, and this is typical in the manufacturing industry.

The majority of the time, individuals work on an assembly line together, adding one part at a time to the final product as the process is repeated over and over again.

Articles that are similar to one another but distinct from one another, as well as articles that are similar to one another but distinct from one another, are manufactured on irregular assembly lines. Such assemblies are frequently used in the furniture industry, where they are used in the production of nearly identical pieces that have varying degrees of cushioned comfort and support to meet the needs of different customers.

To accomplish this task of mechanically transporting semi-finished assemblies from one workstation to another, lean assembly lines, which are a type of production line, are used to accomplish it.

We, the Rompa Group, will be responsible for assembling your items in our assembly lines, which will employ a variety of different technologies to accomplish this.

It is possible for us to produce high-quality electrical circuit boards on our SMT line with our SMT machine as a result of the technology that we have implemented on our SMT line. From 2017 to 2018, the Rompa Group has produced a significant number of printed circuit boards (PCBs) on the surface-mount technology (SMT) line, which was first put into operation in 2017. There have been a large number of printed circuit boards (PCBs) produced by the Rompa Group. Our efforts to streamline the manufacturing process have made it easier to produce electronic components for a variety of different application areas. How important do you think it is for you to understand how our SMT line is constructed and how it is constructed? Specifically, is it a problem caused by the equipment that we have in place for this particular production line, or is the problem caused by something else entirely? If you require any additional information, please see the website listed above.

The information contained in this section relates to the manufacturing footprint of Rompa Corporation.

It is possible to gain access to our production lines from any location on the planet because of our global presence, which is a significant advantage. When it comes to discussing our global footprint, which is still relevant in today's manufacturing processes, and how we can reduce it, there is nothing new for us to say. In fact, we've been talking about it for quite some time already. Because of our numerous manufacturing facilities that are strategically located throughout the world, including China, we are able to provide our clients with a simple means of distributing their products throughout the world. When a manufacturing facility is located close to the final customer, it is not only possible to reduce delivery times, but it is also possible to reduce inventory requirements. Our customers, who appreciate the convenience it provides, also appreciate the assembly flexibility that this method provides, which they consider to be extremely advantageous. In order to maintain a consistent stockflow throughout the year, we agree on the size of the batches as well as the day on which they will be manufactured in advance.

According to your predictions, which of the following events will take place in the near future?

However, human nature dictates that we should continue to seek ways to improve the efficiency of production in the future. The ability to automate processes is a must-have feature for any company! Robots have progressed from their earliest applications in the most basic operations to the point where they are now taking over assembly line in virtually every industry. As a result of technological advancements in recent years, the automation of assembly lines has become more feasible. Despite the fact that some of these lines are completely automated, the vast majority of them require a combination of human and machine labor in order to operate properly and efficiently. Occasionally, human intervention is required during assembly operations because the tasks are too difficult for machines to complete on their own and, as a result, human assistance is required to complete them. Despite the fact that machines perform the vast majority of the work, we have employees who are in charge of the more difficult and delicate tasks that must be completed.

Is it realistic to expect that assembly lines will be completely controlled by computers in the not-too-distant future, based on your observations? You will always require highly trained employees in order to program and develop the assembly process, regardless of whether you are employing cutting-edge technology or not. The collaboration between humans and machines will continue, just as it has done in the past, to help them achieve their objectives in the years to come. On production lines, the use of more recent digital technology, such as the Internet of Things, will be more prevalent, whereas the use of older digital technology will be less prevalent. IoT, or the Internet of Things, is a technological advancement that enables the internet to be used by a wide range of devices, such as your washing machine and refrigerator, to provide them with information.

commentaires