Plastics are among the most commonly used 3D printing materials

Body

The polylactic acid (PLA) used to make this product has the advantage of being biodegradable, as opposed to the ABS used to make it. PLA is made from renewable raw materials, such as corn starch, and is environmentally friendly. Plastic Laminate (PLA) is one of the most straightforward materials to 3D print, though it does have a tendency to shrink slightly after being 3D printed. In contrast to ABS, when printing in PLA, you do not require a heated platform to be used. PLA prints at a lower temperature than ABS, ranging between 190oC and 230oC, making it a more environmentally friendly option.

Because of its rapid cooling and solidification, PLA is a more difficult material to work with than most other materials. It is also important to note that when models come into contact with water, they can become distorted. However, because the material is consistent, easy to use, and available in a wide range of colors, it is well suited for FDM 3D printing applications.

Polycarbonate (PC) is a type of plastic.

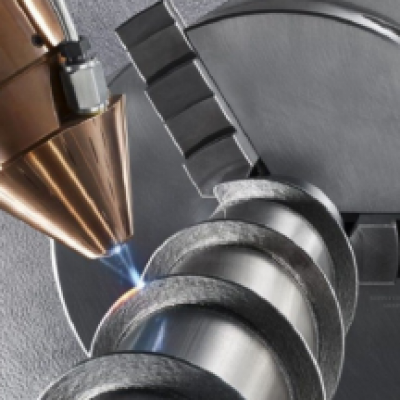

Extensive research into 3D printing materials has resulted as a result of the development of a wide range of high-performance filaments with mechanical properties similar to those of metals, as a result of the advancement of 3D printing technologies. There are several types of high-performance What is 3D Printing plastics available, including PEEK, PEKK, and ULTEM. These plastics are classified according to their chemical family, such as polyaryletherketones (PAEK) or polyetherimides (PEI). Compared to some metals, these filaments have extremely high mechanical and thermal resistance, as well as being extremely strong while being significantly lighter in weight. These characteristics make them particularly appealing in the aerospace, automotive, and medical industries.

High performance polymers are unable to be printed on all FDM machines available on the market due to their unique properties. Indeed, the 3D printer must be equipped with a heating plate capable of reaching at least 230°C, an extrusion capable of reaching 350°C, and a closed chamber to function properly. Approximately 65% of these materials are currently printed using FDM technology, but they are also available in powder form, which is compatible with SLS technology.

Materials that are adaptable

Flexible filaments are a newer type of filament that has proven to be one of the most successful. They are similar to PLA, but are typically made of TPE or TPU instead of PLA. When using these filaments for How Does 3D Printing Work, you can create deformable objects, which are extremely popular in the fashion industry. Flexible filaments have generally the same printing characteristics as PLA, though they are available in a variety of stiffness ranges to suit different printing applications. When What is 3D Printing, it is important to determine which type of extruder is best suited to the material in order to avoid jamming.

Comments