Quality control staff is encouraged during the development of inspection checklists

Body

Collaboration between the importer, the supplier, and the quality control staff is encouraged during the development of inspection checklists for each of the three parties. Importers frequently overlook the importance of collaboration between all relevant parties when developing their quality control checklist, as a result of which they leave it completely out of the process. Due to the fact that this is the most important point, the discussion has unfortunately dragged on for far too long.

It is often possible to gain a better understanding of product requirements, packaging requirements, on-site testing, and defects when you collaborate with your supplier and quality control staff (see related article: 4 People to Consult When Creating a Quality Manual for Your Product for additional information).

So, what exactly is it about collaboration that makes it so valuable in the first place? Perhaps more importantly, how does it tend to result in inspection checklists that are more effective at identifying and precluding potential problems?

You should consult with your supplier about the inspection checklists that will be used before you begin production.

Develop a quality control checklist for your product as soon as possible after receiving your order. This will assist you in ensuring that your product complies with all applicable quality specifications. When it comes to inspection criteria and requirements, if you don't start talking about them with your supplier during the product design phase, you should start talking about them as soon as possible after the product design phase is finished. A straightforward explanation is that high-quality materials and construction techniques are incorporated into product design.

If you're in the business of manufacturing leather bags and the material used in the finished goods is of inferior quality, it's likely that you or your factory will be unable to easily correct a situation if it happens. Manufacturer claims that the product was made of low-quality materials. This is supported by consumer reviews. The end result was a product with poor quality that was ingrained in its design.

In some cases, it is possible to avoid this by clarifying the quality level of material you require for the bags prior to the factory beginning mass production, but in many cases, this is not possible. One of the most effective ways to accomplish this is to work in partnership with your supplier when developing the quality control checklist.

Together with your supplier, you will work through the process of developing inspection standards and product requirements, which will help both of you understand what is expected of you. As a result, there is a lower chance that your supplier will later manufacture a product that does not meet your specifications.

This is due to the fact that many importers' products have failed to pass inspection because they have failed to communicate their quality requirements to their suppliers in an understandable and clear manner. Even if your supplier has their own quality manual, there is no guarantee that it will meet your quality standards.

Perhaps your shoe supplier is producing shoes that are the wrong size for you because you haven't specified the proper measuring method for your shoes when you placed your order. Other possibilities include notifying them of your intention to conduct a specific on-site test and discovering at the time of inspection that they do not have the necessary equipment to conduct the test. This is due to the fact that you failed to notify them that you were planning to conduct the test in the first place. It is also possible that you will find yourself in a situation where you have made an incorrect assumption about a specific component in your product, but your supplier is completely unaware of this.

An inadequate inspection could result in anything from shipping delays and unsaleable products to product recalls and product recalls and product recalls and product recalls and product recalls. Working together with your supplier to develop your checklist provides them with the opportunity to ask questions about the process as it is being developed. Furthermore, you and your team can come to an agreement on the method by which the product will be evaluated.

In order to determine the most effective inspection practices, consult with your quality control team.

As feedback from your supplier helps to ensure that the finished goods meet your expectations, feedback from quality control staff helps to ensure that there is agreement on how to inspect the finished goods once they have been received in your facility. It is more difficult to collaborate on the most appropriate inspection method if you rely on the factory's quality control staff to inspect your product. (For additional information, see Why Most Importers Do Not Rely on Factory Quality Control Staff for Inspection.)You should almost always discuss the inspection procedure with the inspector in advance if you are sending someone from outside to inspect.

Professional quality control inspectors frequently have the knowledge and experience to make significant contributions when it comes to product evaluation criteria, regardless of the criteria that you use to evaluate your product.

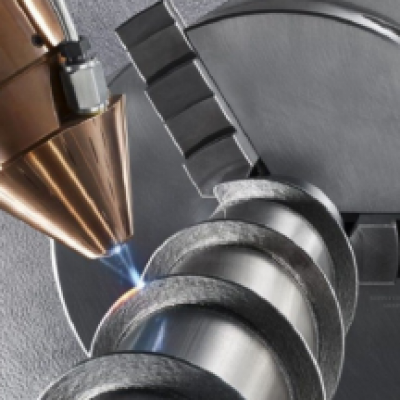

Take, for example, the following scenario: you have no idea what kinds of on-site tests should be carried out or what equipment is required for a thorough inspection of the chairs you are manufacturing in Vietnam. The types of on-site tests that should be performed, as well as the equipment that should be used, to conduct a thorough inspection of the chairs that you're manufacturing in Vietnam, are both possible for you to be unaware of. There are a number of other important factors to consider when creating your checklist, and you can seek advice from the person or company who will be inspecting the chairs on how to go about cmm services properly.

If any of the tests on your checklist are either not feasible or are not relevant to the product in question, an inspector will notify you as soon as possible.

It is recommended that you consult with quality control personnel as part of the checklist development process to ensure that there are no surprises when the inspection is performed and that you receive an accurate report. As a bonus, this is one of the quickest and most straightforward methods of ensuring that those who are inspecting your product are essentially looking at it with the same pair of eyes that you would be using to examine it yourself is also one of the most straightforward.

According to the article Should You Develop Your Own Quality Manual or Hire an Outside Quality Assurance Professional to Assist?, a number of third-party inspection companies will collaborate with you to develop a customized checklist for your product.

Having learned about the five essential elements that should be included in any effective quality control checklist, how do you go about creating your own quality control checklist?

In order to develop effective inspection checklists, it is necessary to work together with other people. Discussions with your supplier are critical in this regard. Inform the inspector of your expectations for the product, your desire for a thorough inspection, and the aspects of the product that you believe should be scrutinized during the inspection process before the product is delivered. If at all possible, speak with a quality control manager at the factory that is manufacturing your product in order to voice any issues or concerns you may have about the finished product's quality before submitting your complaint.

Inform any third-party quality control personnel who will be inspecting your product before it is put into production of the inspection procedure you have developed. Inquire as to whether or not they would recommend performing any of the industry-standard on-site tests and checks, as well as how many samples of goods they would recommend testing and checking.

As a result, depending on the type of product you're selling, your budget, and the demographics of the market you're trying to reach, quality expectations are likely to differ. The fact that this is the case should also be reflected in your checklist at some point.

More than anything else, the author of this article wishes to emphasize the importance of having a thorough quality control checklist that addresses all aspects of your product that have been discussed in this article. If you believe something is not important enough to include in your checklist, keep in mind that your supplier and any quality control personnel are likely to believe the same thing as you do.

Comments