-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

- Tags - #Aluminum Die Casting

-

- Last updated April 13, 2022 0 comments, 88 views, 0 likes

More from Baby wu

More in Politics

Related Blogs

When it comes to LED lamps the heat sink made of aluminum alloy that is used to cool the LEDs

Body

An investigation into the aluminum die casting parts heat sink, which is a critical component in determining the performance and service life of LED lighting.

It has been shown that the heat sink, which is made of aluminum casting, has a significant impact on the performance and service life of LED lighting.

The researchers discovered that only 30-40% of the electric energy emitted by LEDs is converted into light energy, with the remaining portion being converted into heat energy, after taking a variety of factors into account. Even though an LED chip's luminous efficiency is 100 percent when the temperature is kept at 25 degrees Celsius, the efficiency drops to 90% when the temperature is raised to 60 degrees Celsius; when the temperature is raised to 100 degrees Celsius, Aluminum die castings drops even further; the luminous efficiency at 140 degrees Celsius is only 70% when the temperature is raised to 150 degrees Celsius. It becomes more difficult to deal with the heat dissipation problem when multiple LEDs are densely arranged to form a white light lighting system. It will only be possible to manufacture high-brightness LEDs once the heat dissipation problem has been resolved.

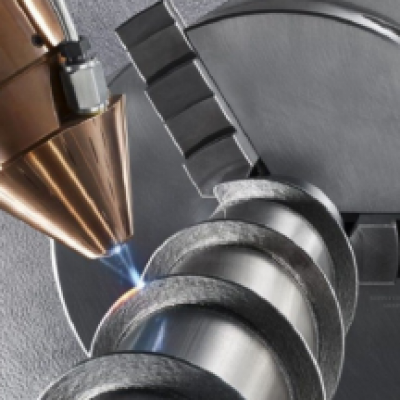

Most LED radiators currently available on the market are fin-type heat dissipators made of die casting aluminum, which are the most common type of heat dissipator currently available on the market. It is an excellent heat conductor because of its extremely high thermal conductivity, which is a property of aluminum die casting. In terms of appearance, the die-casting radiator is lightweight and easy to handle, and it has a beautiful sperm pattern on the surface of the radiator that adds to its appeal. Furthermore, the fin type heat dissipation design makes optimal use of the available space in the design while also taking into consideration air convection and other factors, resulting in an extremely favorable heat dissipation effect overall. Besides that, it has the potential to prevent damage to the lamp's body while also increasing the lamp's impact resistance. It is also recyclable and non-polluting to the environment, making it a good material for recycling. This aligns with the concept of LEDs as environmentally friendly light sources. Shenzhen zinc alloy die casting factory, which has provided a variety of models of aluminum alloy die casting LED lamp heat sink to their customers, has benefited from the services of a large number of manufacturers. The vast majority of people spray white on the heat sink and then bake it for a few minutes in the oven to finish it off. Despite the fact that, at the present time, LED lamps are unable to compete on price with traditional energy-saving lamps due to technical limitations, the future of LED lighting looks bright as technology advances.

Comments