-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

- Tags - #Auto Parts Factory

-

- Last updated July 7, 2020 0 comments, 388 views, 0 likes

More from ritchie silways

More in Politics

Related Blogs

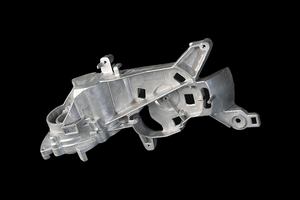

Auto Parts Factory-Reasons For Choosing Die Casting Process

Body

Die casting is a popular manufacturing process used to cast metal products. There are two main types of die casting process, and several changes in process design. When molten metal is forced into the cavity under high pressure, it is called die casting. This process is best suited for the rapid production of bulk metal parts that require minimal post-processing. The main advantages of the die casting process include:

High quality: Parts made by die casting have a long service life.

High reliability: The uniformity of mass-produced parts is excellent.

Fast production: The minimum maintenance required for die-casting molds.

Multi-functional design: Die casting can produce almost any size, part geometry, surface texture or gloss.

Minimal assembly: stud, drilling and boss assembly functions can be integrated into the mold design

Jiaxing Yunhe Trading Co., Ltd. is a professional Auto parts factory in China. High-quality supply of aluminum alloy die-casting, zinc alloy die-casting and other non-ferrous metal die-casting products, we have a wealth of production experience, supporting production equipment and skilled die-casting workers, to ensure that orders are completed in accordance with quality and quantity. Welcome to consult and order: https://www.xinxinmetal.com/product/car-accessories/

Comments