A Comprehensive Guide to Springs

Body

Springs play a crucial role in various mechanical applications, utilizing the elasticity and structural properties of materials to achieve deformation and energy storage. This article explores the classification, parameters, and marking of springs, shedding light on their diverse applications in mechanical components.

Classification of Springs:

Springs come in various types, including coil spring, leaf spring, spiral spring, and disc spring. Among them, the cylindrical spiral spring stands out for its simple structure, convenient manufacturing process, and widespread applications. This type further divides into compression spring, extension spring, and torsion spring.

1.1 Compression Spring:

Characterized by large energy storage, low compression height, and stable stiffness, compression springs find applications in buffering, vibration reduction, energy storage, and controlling movement in mechanical equipment. They are commonly used in engine valve mechanisms, clutches, and automatic transmissions.

1.2 Extension Spring:

Similar to compression springs in performance and characteristics, extension springs are employed in situations requiring tensile load support, such as in overload safety devices of couplings.

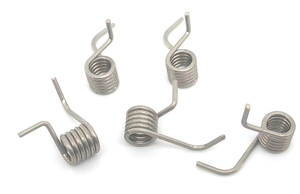

1.3 Torsion Spring:

Primarily used for compression and energy storage, torsion springs serve as elastic links in transmission systems to withstand torsional loads. With linear characteristics, they are applied in dynamometers and forced air valve closing mechanisms.

Parameters of Springs:

Understanding the parameters of springs is essential for selecting the right type for specific applications.

2.1 Wire Diameter (d):

The diameter of the wire winding the spring.

2.2 Inner Diameter (D1), Outer Diameter (D2), and Pitch Diameter (D):

The inner diameter, outer diameter, and pitch diameter are crucial dimensions of the spring, where D is the average of D1 and D2.

2.3 Pitch of the Spring (t):

The axial distance between the section centerlines of two adjacent coils, excluding the support rings.

2.4 Number of Supporting Rings (nZ), Effective Number of Rings (n), and Total Number of Rings (n1):

To ensure uniform stress distribution, springs have supporting rings. The effective number of rings excludes support rings and is calculated as n = n1 - nZ.

2.5 Free Height (H0):

The height of the spring without any load.

2.6 Stretched Length of Spring Wire (L):

The length of the steel wire used for winding the spring.

Marking of Springs:

Properly marking springs is crucial for identification and application. The end coils can be either tightly ground (Type A) or tightly forged (Type B).

Example of Spring Marking:

YB 30x150x300 GB/T 2089-2003: Cylindrical spiral spring, wire diameter Φ30mm, pitch diameter Φ150mm, free height 300mm, manufacturing accuracy grade 3, material 60Si2MnA, surface painted, and can be left-handed or right-handed.

YA 1.2x8x40-2 GB/T 2089-2003: Cylindrical spiral spring, wire diameter Φ1.2mm, pitch diameter Φ8mm, free height 40mm, manufacturing accuracy class 2, material class B carbon spring steel wire, surface galvanized.

Summary:

This article provides an overview of spring classification, parameters, and marking. While standard springs are preferable for most design work, non-standard springs can be designed and customized under special circumstances to meet specific requirements. Understanding these aspects ensures the optimal selection and application of springs in various mechanical systems.

Comments