-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

- Tags - #Thickener Tank #mixing equipment factory

-

- Last updated September 26, 2018 0 comments, 540 views, 0 likes

More from tank mixing

More in Politics

Related Blogs

Archives

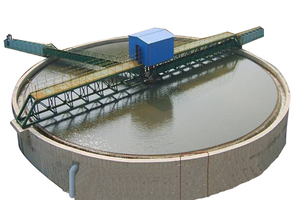

What are the main uses of Thickener Tank

Body

The most common solid-liquid (S / L) unit operation is thickening. Various thickening tanks are used, including conventional deep wells, slurries, high-speed and clarifiers, which are subclasses of thickeners used to remove solids from turbid or very low solid water. Thickener Tank is a mechanical continuous process equipment, it operates according to the particle / flocculation sedimentation principle, in the simplest terms, is the solid settlement to thickening tank bottom, overflow tank.

The accepted basal elements of thickeners include:

A) Inlet: The slurry or baptize is alien into the concentrator to absolute active activity entering the water, abbreviate turbulence throughout the tank, and adviser bottomward into the concentrator.

B) Rake mechanism: or agnate accessory that pulls acclimatized solid/mud to the centermost of the tank; it plays an added important role in abolition the mud and absolution the added damp retained by the clearing mud as the rake passes through the mud.

C) breeze pump: it can be disconnected into edge type, centrifugal type, diaphragm blazon and accelerating atrium type.

Many factors will affect the amount of reagent required for specific applications. Specific size, particle mass, mineral mass, and rock properties are some of the factors that affect the use of reagents.

Water quality, flotation equipment size and type, temperature and orebody changes are only a few variables that affect the flotation process.

You can click mixing equipment factory for more information.

Comments