-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

- Tags - #Aluminum Die Casting

-

- Last updated June 23, 2020 0 comments, 236 views, 0 likes

More from wei long

More in Politics

Related Blogs

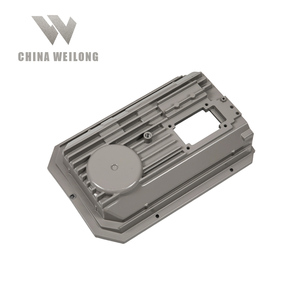

Production Process Of Aluminum Die Casting

Body

In recent years, the requirements of industrialization for Aluminum Die Casting are getting higher and higher. In the whole process of production and application, the professional knowledge of aluminum die casting production and manufacturing, such as die casting die load, stress relaxation and cracking, and die casting die service life, is delicate.

With the increasing requirements of industrialization for die-casting dies, the aluminum die-casting manufacturing industry encounters more opportunities and faces many challenges.

As you can see, in the production process of aluminum die casting:

The number of single aluminum die casting increased.

The working pressure of aluminum die casting increases.

The forming time of aluminum die casting increases.

The automatic technology of production and manufacturing of aluminum die casting has made the standards in the work of die casting dies more stringent.

In the die casting process, the internal heat conduction mode of the metal composite material is transmitted according to heat conduction.

The heat conduction mode on the steel surface: heat convection mode and radiation source heat conduction.

The way of heat conduction in steel: transmission heat conduction.

When the temperature rises, the compressive strength of metal materials decreases. Therefore, air temperature is harmful to the quality of casting parts and the metal composite materials of casting parts that cannot be twisted.

In view of the service life of die casting dies, the higher the extensibility and ductility of metal materials, the higher the tensile strength and compressive strength, so as to achieve the predicted quality of castings.

Zinc Die Casting is also one of our product, welcome to buy and purchase!

Comments