-

Find in Members

Find in Members Find in Videos

Find in Videos Find in Channels

Find in Channels

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Click herePrivacy Preference

- Tags - #China Zinc Die Casting Manufacturer

-

- Last updated August 18, 2020 0 comments, 300 views, 0 likes

More from wei long

More in Politics

Related Blogs

The Demand For Zinc Die Casting Is Increasing Rapidly

Body

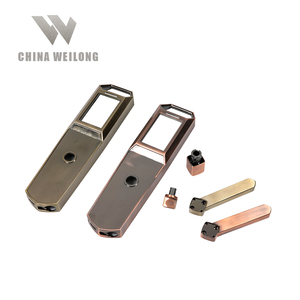

As we all know, zinc die casting is widely used, especially in digital parts, electronic parts, furniture parts, architectural decoration, bathroom parts, lighting parts, toys, tie clips, belt buckles, various metal decorative buckles and other zinc die casting, which are in great demand. In recent years, China's traditional enterprises have developed rapidly, and the demand for zinc die casting has increased rapidly, which has greatly promoted the development of China Zinc Die Casting Manufacturer.

Because zinc die casting is one-time die casting, with high production efficiency and low processing cost, it is especially suitable for parts with less strict tolerance and complex geometry. It has been widely used to replace structural parts and decorative parts with less stress and complex shape made of copper, copper alloy and iron and steel materials, and its surface treatment process is also in the mature stage.

Zinc die casting is an alloy mainly made of zinc and supplemented by aluminum, and its chemical stability is poor, so it needs to be protected by other metal layers, and electroplating layer is one of them. However, we should know the ratio of zinc and aluminum content before electroplating zinc die casting. If the aluminum content is too high, the oxidation of the surface layer will be accelerated, resulting in a decrease in the adhesion of the coating; if the aluminum content is too low, the toughness of the parts will be affected, and it is easy to break during use. From the point of view of electroplating and its application, the aluminum content in the alloy should be between 3.5% and 4%. Whether the pretreatment of zinc die casting is reasonable or not is the key to the success of electroplating.

After surface treatment, the products of zinc die casting is not only beautiful in appearance and unique in shape, but also corrosion-resistant, wear-resistant, fall-resistant, strong in impact resistance and durable in texture.

Aluminum Die Casting is also our hot product, if you are interested in our products, you can click our website: https://www.chinaweilong.cn/

Comments