-

Retrouver dansMembres

Retrouver dansMembres Retrouver dansVidéos

Retrouver dansVidéos Retrouver dansChaînes

Retrouver dansChaînes

This website uses cookies to ensure you get the best experience on our website.

To learn more about our privacy policy Cliquez iciPréférence de confidentialité

- Mots clés - #OEM aluminum enclosure Die casting manufacturer

-

- Dernière mise à jour 3 février 2021 0 commentaire , 279 vues, 0 comme

- Yuyao, Ningbo, Zhejiang, China - Obtenir des directions

More from wei long

More in Politics

Related Blogs

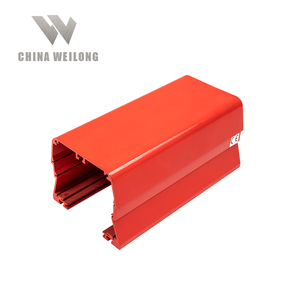

Features Of OEM Aluminum Enclosure

Corps

There are many types of OEM aluminum enclosure on the market. Aluminum enclosures mainly use mid-surface stress uniformly distributed along with the thickness instead of bending stress along the thickness to resist external loads. Let's take a look at the plastic shell charger shell and its characteristics.

Plastic shell The charger shell is a shell produced from a plastic material through an injection molding machine. There are charger shells, adapter shells, power supply shells, switching power supply shells, industrial power supply shells, inverter shells, LED power supply shells, and aluminum Profile shells are processed by supplied materials. Good-quality hardware shells have significant differences in performance. These hardware shells are diverse in variety, widely used, and have broad prospects.

No matter what type of aluminum housing, it has its unique advantages and functions. So choose the one that suits you when shopping. At present, Die casting manufacturer is constantly developing and improving the aluminum shell products. There are more types of products, which is not a bad thing for us.

Photos

Carte

-

Emplacements sur MyWorldGo

Information de Lieu

- Emplacement: Yuyao, Ningbo, Zhejiang, China - Obtenir des directions

- Adresse formatée: Yuyao, Ningbo, Zhejiang, China

- Adresse de rue: Ningbo

- Etat: Zhejiang

- Pays: China

commentaires